Results for ""

During the pandemic, there prevailed an urgency for food manufacturers to explore new automation options in order to fill their store shelves which were left empty by the supply chain bottlenecks.

A report by Honeywell found that around 59% of food and beverage businesses are ready to invest in automation after the pandemic strike.

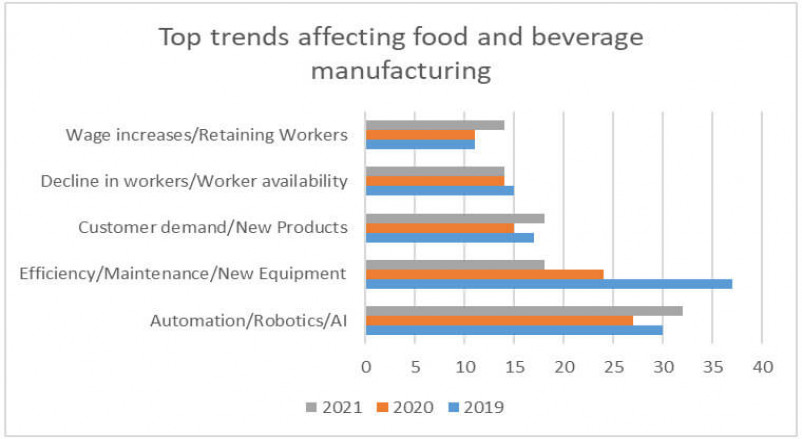

As per the Food Engineering’s annual State of Food Manufacturing Survey, automation or robotics or AI was the top trend which is expected to enhance food manufacturing in the next five years.

Food Engineering's State of Food Manufacturing Survey results

But studies have made it clear that as food manufacturers get smarter, there will be another bottleneck: a shortage of data scientists to develop AI solutions that optimise food production processes. There is another hurdle: most food manufacturers have the misconception that AI is too expensive, complex and inaccessible for common manufacturers. Here every food manufacturer can develop their own data to reduce the impact of supply-chain disruptions by implementing intuitive AI solutions leveraging No-Code visual programming platforms.

What is No-Code AI?

No-Code platforms make AI possible without the need for actual software programming. Writing codes are not necessary as through self-service analytics; we will be able to connect, prepare and model data which opens the world of advanced analytics to the ones who lack experience in computer programming. Earlier, food manufacturers were forced to rely on data scientists to program complex algorithms. But with the arrival of no-code platforms, skilled data analysts can visually program advanced solutions, accelerating the speed and effectiveness of AI in supply chain management.

Food manufacturers can extensively use No-Code AI solutions to optimise their supply chains in three ways:

No-Code AI for demand optimisation

Demand forecasting using AI will be the primary AI solution that food manufacturers can use to observe their supply chains, as demand forecasting is the starting point for most supply-chain processes in food manufacturing. Hence it is significant for all supply chain-related decisions. Demand forecast AI is designed in a way that it learns from past historical product performance to predict future demands. This helps the food manufacturers who struggle with the skyrocketing price of production staples. AI for demand forecasting is considered an accurate strategic analytics tool for food manufacturers to allocate rare resources and anticipate purchasing efforts with enough time to minimise the potential shocks from slow supply chains.

No-Code AI for inventory optimisation

AI for inventory forecasting is the second most AI solution that food manufacturers can utilise to observe their supply chains. This helps them address the supply chain disruptions by offering the food manufacturers optimal inventory levels to enhance the production and logistics plans. The deployment of AI in inventory optimisation reads data from the inventory management systems and analyses the previous demands to predict optimal stock levels. A well-developed AI inventory forecasting solution, will sync data across all platforms to ensure all orders and stocks are accounted for.

The use of No-Code AI in inventory forecasting can be based on advanced time series methods like Long-Short Term Memory Networks or any other Recurrent neural Networks with sliding time windows to process sequential inventory data. This helps AI to learn and optimise the patterns over time.

No-Code AI for traceability optimisation

The third most AI solution that aids food manufacturers in observing the supply chain is the optimisation of traceability. Traceability helps food manufacturers keep track of the movement of products and ingredients in every step of the supply chain and manufacturing process. The traceability systems are important for the food supply’s health and safety. Regarding food contamination, the connection between food producers, processors and distributors is maintained to allow faster removal of contaminated food, which helps minimise the friction in the supply chain and enhances food manufacturers’ agility during disruptions.

No-Code AI for traceability solution helps food manufacturers:

- Keep track of entire inputs and outputs for complete visibility

- To get connected to all existing data sources

- Automatically spot food safety issues

- Comply with the whole regulatory requirements

- Complete everything above without spending a single penny.

Sources of Article

- Photo by Deva Williamson on Unsplash